Measuring KPIs is not a theoretical exercise—it’s the difference between retaining contracts, avoiding penalties, accelerating invoicing, and proving service traceability to the client. In industrial cleaning and facility services—where field teams, supervisors, routes, and constant audits are the norm—measuring the right indicators is critical.

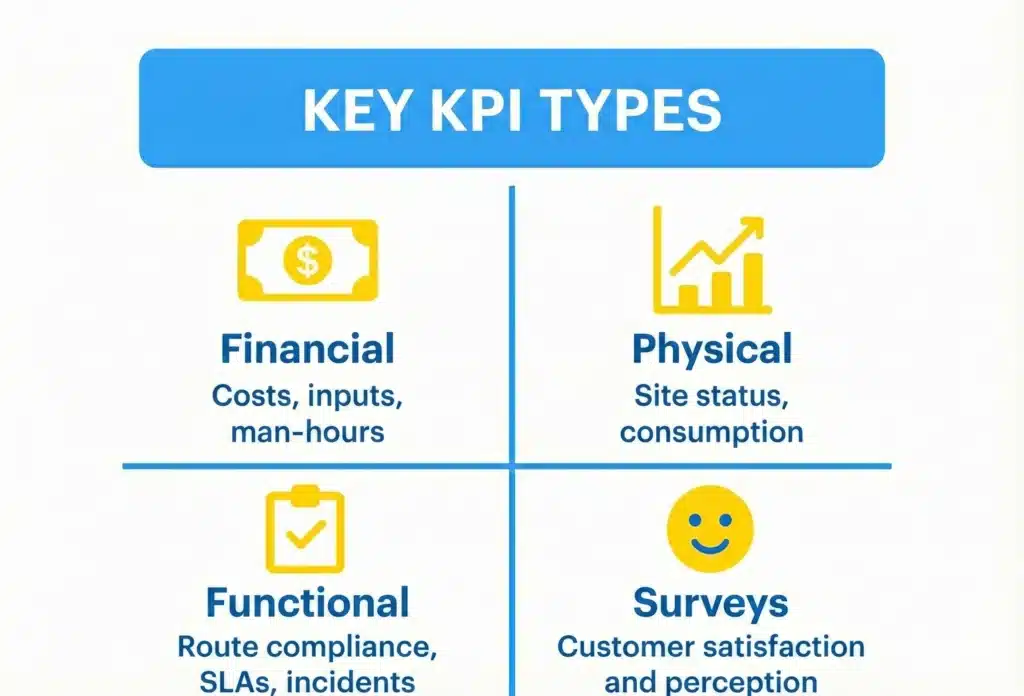

Based on specialized literature and hands-on experience in LATAM, these are the 4 essential types of KPIs every company should measure (and that most are currently measuring poorly).

Why KPIs Are Vital in Industrial Cleaning

Industrial cleaning companies operate under:

- Contracts with demanding SLAs

- Audits (HACCP, hygiene, quality)

- Complex routing and planning

- High turnover and attendance control needs

- Clients requiring service evidence (photos, GPS, signature, timestamp)

Without clear KPIs and reliable data, it becomes almost impossible to:

- Avoid penalties for non-compliance

- Prepare automatic client-facing reports

- Justify rate increases or renewals

- Control margins affected by rework and supplies

- Compete successfully in bids

The 4 Types of KPIs Every Industrial Cleaning Company Must Measure

1. Financial KPIs — Cost Control and Margin Protection

These KPIs answer:

How much does it cost us to deliver the service? And how much does it cost when something goes wrong?

Key indicators

- Cleaning cost per m² / per site

- Cost per incident / ticket

- Corrective vs. preventive cost

- Supplies cost per service

- Planned vs. executed labor hours

Why they matter

They help compare sites, negotiate contracts, protect margins, and justify rate increases as workload grows.

2. Physical KPIs — Facility Condition and Consumption

These KPIs answer:

How demanding is the site? What conditions and resource consumption affect operations?

Key indicators

- Facility Condition Index (FCI)

- Energy consumption per m²

- Waste generation / recycling rate

- Condition of restrooms, critical areas, and high-traffic zones

Why they matter

Deteriorated or high-demand sites require more resources, more labor hours and more supplies.

3. Functional KPIs — Execution, Compliance and SLAs

These are the KPIs clients care about the most. They answer:

Are we delivering what we promised?

SLAs (Service Level Agreements) define minimum service standards: cleaning frequency, response times, minimum staffing per shift, required evidence (photo, GPS, signature) and quality conditions in the contract. Non-compliance typically results in penalties, invoice discounts or non-renewals.

Key indicators

- Completion of scheduled cleaning

- Mean response time to incidents

- Rework per site / per supervisor

- Compliance with supervision routes

- Tasks completed with evidence (photo, GPS, signature)

- Non-conformity rate in audits

Why they matter

They appear in almost every bid, audit, renewal process, and penalty claim.

4. Survey-Based KPIs — Client Satisfaction and Perception

These KPIs answer:

How satisfied are clients and users with the service quality?

Key indicators

- NPS / client satisfaction

- Perceived hygiene in critical areas

- Client audit results

- User-reported non-conformities

Why they matter

Renewals depend as much on client perception as on operational KPIs.

KPIs Typically Required in Bids

In industrial cleaning bids, clients demand clear evidence of operational compliance. They typically request KPIs such as task completion rates, photographic evidence, GPS validation of staff, compliance with supervision routes, response times, and non-conformity rates. They also expect control of supply consumption, delivered labor hours, and periodic automatic PDF reports.

Why Most Companies Fail to Measure These KPIs

Although these indicators are industry-standard, most companies struggle to measure them correctly. Data is scattered across paper, WhatsApp, and Excel, making consolidation difficult. Supervisors are overloaded collecting evidence manually, and many operations lack complete proofs (photo, signature, GPS). Reports are slow and manual, and the lack of integration with HR or ERP complicates validation of hours and staffing. Field teams often work in areas with limited connectivity and no offline mode.

How DataScope Helps Automate These KPIs

1. Full Service Traceability

- Checklists with photos, GPS, signature, timestamp

- Automatic evidence for SLAs

- Offline mode

2. Attendance and Shift Control

- GPS/photo/biometric validation

- Absence alerts

- Attendance tracking

3. Automated SLAs and KPIs

- Automatic PDF reports

- Real-time dashboard

- KPIs of compliance, incidents, routes, supplies, and more

4. OT → Evidence → Signature → Invoice Flow

- Reduces days to invoice

- Avoids rejections

- Automates service closure

5. Client Portal for Bids and Renewals

- Clients view evidence without requesting it

- Increases renewal rate

Practical Guide to Start Measuring Better

- Select 6 critical KPIs

- Digitize checklists, incidents, and attendance

- Configure dashboards and automatic reports

- Align KPIs with contract SLAs

- Review KPIs monthly and adjust per site

Conclusion

Companies that measure these KPIs consistently gain immediate operational advantages: fewer penalties, faster invoicing, standardized supervision, better margins and stronger bid performance. As operations become more predictable, they not only win more contracts—they keep them longer.

The most efficient way to achieve this is with a platform built for field operations like DataScope.